Ever wondered how top tech companies stay a cut above when it comes to wire management? Brace yourself, because the secret might just surprise you. Automatic wire stripping machines are revolutionizing the way industries handle cables.

In today's fast-paced world, efficient wire processing has never been more critical. From tech giants to DIY enthusiasts, the demand for precision and speed is driving the popularity of these ingenious devices.

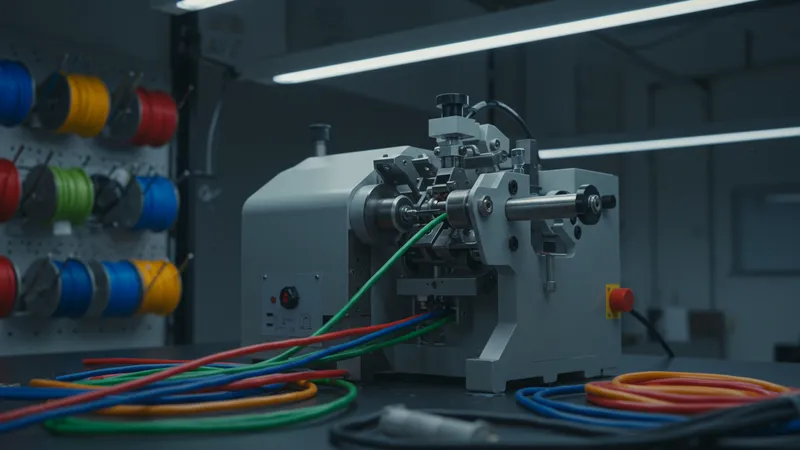

Many assume wire stripping is straightforward, but the complexity and variety of wires can pose unexpected challenges. These machines, equipped with technology that adapts to various types of insulation and wire gauges, solve puzzles that once required hours of manual labor. But that's not even the wildest part…

Some models can even integrate with smart systems, optimizing efficiency beyond imagination. Imagine a machine that not only processes wires but also provides real-time analytics on your workflow. This capability has transformed manufacturing floors worldwide. However, there's still more to uncover in this electrifying industry…

What happens next shocked even the experts in the field, as new advancements continue to turn traditional methods on their heads. Prepare to dive deeper into a world where technology meets everyday practicality in our exploration of the best automatic wire stripping machines.

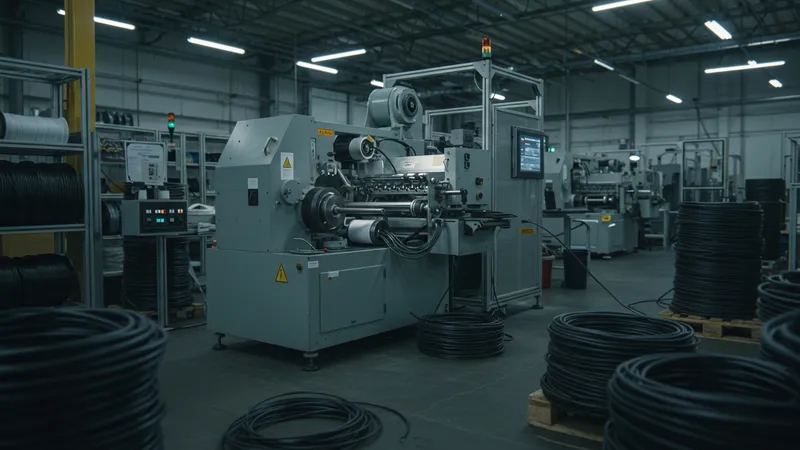

Automatic wire stripping machines have long been considered a niche tool, yet their efficiency tells a different story. Companies that integrate these machines report up to a 75% increase in production speed, a statistic that challenges the manual traditions which have dominated the industry for decades. This leap in productivity isn’t just about speed—it's a complete transformation.

The magic lies in the machine's ability to adapt. Unlike manual methods, these machines automatically adjust to different wire types and sizes, reducing errors and waste. This feature alone saves companies thousands of dollars annually, a financial perk that's catching the eyes of even the most skeptical business owners. But there's one more twist you didn't see coming...

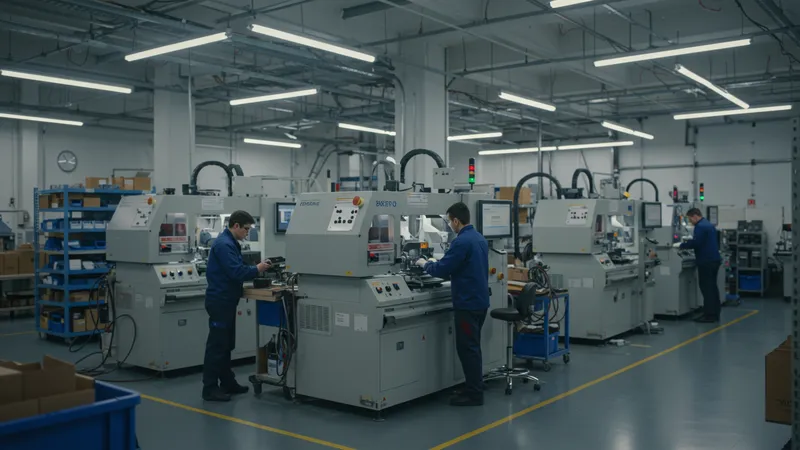

For small businesses and home-based makers, the shift towards automation is no less important. Suddenly, intricate and previously difficult projects become not only accessible but also profitable. Automatic wire stripping machines remove the intimidation factor, bringing sophisticated capabilities into garages and small workshops. What you read next might change how you see this forever.

Yet, the underrated advantage of these machines lies in safety. By eliminating the repetitive strain and reducing the risk of injury from manual stripping, these tools have become a staple for ensuring workplace health. As you’ll discover, the journey to mastering this technology reveals layers of unexpected benefits.

As industries focus more on sustainability, automatic wire stripping machines are stepping up with their eco-friendly approach. By minimizing waste through precision cuts and optimizing resource use, these machines reduce the environmental footprint of wire processing—a concern growing hotter by the day.

Many manufacturers are taking it a step further by incorporating eco-friendly materials and recyclable parts within the machines themselves. This dedication to sustainability matches the increasing demand from consumers who expect companies to take responsibility for their environmental impact. But there’s more innovation waiting in the wings…

For industries handling vast amounts of wiring, the efficiency of wire stripping machines results not only in conservation of resources but also significant cost savings. Energy-efficient models can cut power usage by half, making them an attractive option for companies looking to reduce overheads while claiming a greener identity.

These developments pave the way for a new standard of eco-conscious engineering. Automatic wire stripping machines aren't just saving money—they're setting the benchmark for responsible manufacturing. But just how far can these advancements go in reshaping the wire industry? Let's dive deeper.

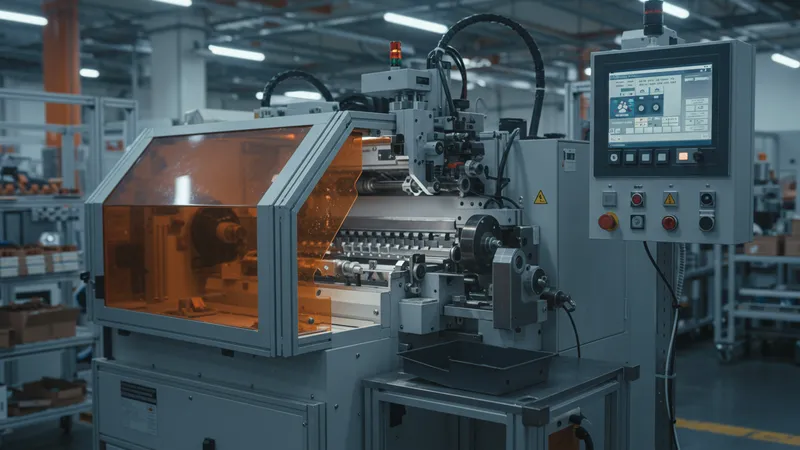

Incorporating artificial intelligence into automatic wire stripping machines has been a game-changer. With AI's ability to learn and adapt, these machines are becoming smarter, managing complex tasks that once demanded human intervention, leading to unparalleled levels of convenience.

Companies are now leveraging these capabilities to monitor wire processing in real-time. Smart sensors and data analytics enable proactive maintenance, reducing downtime significantly. Imagine machines foreseeing issues before they even occur, ensuring a seamless production line. What comes next pushes the envelope even further.

This intelligent approach is not just theory—businesses implementing AI-integrated machines have seen error rates plummet, product integrity rise, and customer satisfaction soar. Such benefits drive the industry forward, prompting further exploration of AI applications in other areas of manufacturing.

The future could hold machines that not only perform flawlessly but also evolve, learning from each task to refine their operations. As technology continues to advance at a dizzying pace, we’re only scratching the surface of what's possible with automatic wire stripping machines.

The upfront cost of an automatic wire stripping machine can be daunting, but the long-term benefits often overshadow the initial investment. With potential savings in labor, materials, and production time, many businesses find that these machines pay for themselves much faster than anticipated.

However, not all machines are created equal. Quality and features can vary widely, necessitating careful consideration and thorough research before purchase. Yet, those who do invest often discover that the boost in efficiency and reduction of errors far outweigh the costs. There's an even bigger economic angle to consider, though...

For growing businesses, the opportunity to scale operations with these machines is transformative. As demand increases, the ability to meet production goals without compromising quality becomes a significant competitive advantage, turning a purchase into a strategic growth tool.

Ultimately, the decision to invest doesn't just boil down to cost—it's about envisioning the future potential these machines unlock. As we’ll explore, the true value emerges from integrating these tools effectively into your workflow.

Once deemed a luxury for large corporations, automatic wire stripping machines are breaking out of this mold. New models are emerging with competitive pricing, making them accessible to small businesses and individual innovators, democratizing the world of automated wire processing.

Manufacturers are responding to this shift by offering flexible pricing, financing options, and even rent-to-own schemes, facilitating adoption across different sectors. These accessible options empower everyone from seasoned professionals to hobbyists, but there's a hidden gem yet to be discussed...

The accessibility extends beyond cost. User-friendly designs mean that even those with minimal technical expertise can utilize these machines effectively. Intuitive interfaces and clear instructions are making it easier for users to navigate complex tasks with confidence.

This newfound accessibility is poised to inspire a wave of innovation, as more creators have the tools needed to experiment and develop new projects. Next, let's explore how these machines are fostering creativity and collaboration across industries.

Automatic wire stripping machines are doing more than just streamlining production—they’re sparking creativity and collaboration. With barriers lowered, teams can focus on what truly matters: innovation and quality, encouraging a culture of creativity.

In research and development settings, quick prototyping is essential. These machines facilitate faster iterations, enabling teams to test concepts without delay. This agility accelerates project timelines, but there's another layer enhancing collaboration even further...

By integrating these machines into educational environments, schools and colleges are harnessing their potential to teach students about automation and engineering. Providing hands-on experience with cutting-edge technology prepares the next generation of innovators and opens up exciting career pathways.

Collaboration also extends to industry partnerships, where shared access to advanced tools can lead to groundbreaking products and solutions. This convergence of education, innovation, and industry propels us into a new era of technological advancement.

While the primary focus is often on efficiency, safety improvements brought by automatic wire stripping machines are equally noteworthy. By automating tasks that traditionally involved manual intervention, the risk of injuries from repetitive strain is significantly reduced.

These machines are designed with safety features like emergency stop buttons and protective enclosures, ensuring that operators are shielded from potential hazards. But there’s an often overlooked advantage that makes a huge difference...

Work environments become safer when these machines are used, not just because of reduced physical strain, but due to minimized contact with potentially harmful materials. This prioritization of health and safety contributes to a more positive workplace culture and elevates operational standards.

As more industries adopt these technologies, the emphasis on creating safer workplaces continues to grow, illustrating how tech advancements are intertwining with human-centric priorities. What could possibly come next? Let’s delve into the potential future enhancements.

As no two production lines are identical, the evolution of customizable automatic wire stripping machines has allowed for tailored solutions. Features can be adjusted to meet specific requirements, providing businesses with the flexibility they demand in a competitive landscape.

Companies now have the option to incorporate bespoke features like adjustable blade mechanisms, specialized feeding systems, and programmable controls. This customization enhances precision and efficiency while aligning with industry-specific regulations. But what lies beyond customization?

The adaptability of these machines extends their life cycle, making them a robust investment. With the potential for upgrades and modifications, businesses can evolve these tools in sync with technological and operational advancements. This adaptability is crucial for staying ahead in a fast-paced world.

But does this flexibility impact the machine's reliability? On the contrary, continuous developments in design and engineering have ensured that advanced functionality does not compromise sturdiness. Our next exploration will uncover the durability and maintenance aspects that solidify these machines' reputation.

Robust construction is a defining trait of quality automatic wire stripping machines. Engineered to withstand the rigors of industrial use, these machines boast long lifespans that maximize return on investment and minimize outages.

Regular maintenance, often emphasized by manufacturers, keeps the machines at peak performance. Comprehensive guides and readily available parts simplify upkeep, reducing downtime that could otherwise impact productivity. But there's an under-the-hood innovation that makes maintenance even more accessible...

Many machines now incorporate diagnostic features that alert users to potential issues before they become problems. This proactive approach to maintenance ensures that production keeps flowing smoothly and prevents costly repairs.

This durability isn’t just about construction; it's about ensuring that these machines continue to deliver value year after year. As we journey further, the insights into maintenance practices will shed light on what really makes these machines shine in day-to-day operations.

Automatic wire stripping machines are not just tools—they're setting a new standard for what’s possible in manufacturing and beyond. By seamlessly blending technology with practicality, they redefine efficiency and open avenues for innovation.

Industries embracing these machines are witnessing renewed vitality, thanks to the ripple effect of enhanced productivity and reduced costs. These efficiency gains unlock new opportunities and inspire others to follow suit. But one question remains—what unseen potential might still be waiting?

As more businesses witness success stories, the buzz around automatic wire stripping machines is turning skeptics into advocates. This growing community shares insights, tips, and experiences, amplifying the benefits across diverse sectors.

With technology continuing to evolve, the continuous enhancement of these machines signals a thriving future for those willing to embrace change. Our journey through this world of innovation is far from over, as we uncover more of what these machines bring to the table.

For many, the shift to automatic wire stripping machines represents a leap into the unknown. The transformation required can be daunting, yet the rewards prove worthwhile. Businesses ready to embrace this change often find themselves at the forefront of innovation in their field.

Adopting these machines requires more than just purchasing equipment; it’s about embracing a mindset of progress and adaptation. Once this shift occurs, the opportunities for growth, efficiency, and creativity expand exponentially. But there’s a secret to seamless adoption...

Companies strategizing comprehensive training and support for their teams find the transition smoother and more rewarding. Employees equipped with knowledge and confidence in these technologies drive success from within, turning apprehensions into enthusiasm.

Closing the gap between potential and reality is a collaborative effort involving training, courage, and vision. This is where pioneers separate from traditionalists, unlocking extraordinary capabilities through automated wire stripping technology. What does this mean for the future? The final piece of our journey awaits.

Beyond practicalities, automatic wire stripping machines are inspiring a broader revolution—one where perspectives shift, and old norms are continuously challenged. The impact extends beyond industrial floors, prompting a reassessment of what’s feasible across domains.

This technological catalyst has even reached the creative industry, where artists and designers use these machines to experiment with new materials and concepts. The cross-pollination of ideas fuels a renaissance of ingenuity and exploration. But there’s still more ground to cover...

The revolution echoes through education and community initiatives, initiated by the accessibility of these previously exclusive tools. As individuals and small teams bring grand visions to life, the full power of innovation shines brightly.

The ripple effect continues, as the proliferation of automatic wire stripping machines transforms from an industry niche into a widespread movement. What’s next may forever reshape views of technology as not only a tool but as an integral part of the creative and productive ecosystem.

With automatic wire stripping machines marking their territory in manufacturing, the horizon is limitless. Future developments promise even more integration with AI, eco-friendly features, and unparalleled precision, setting the standard for the coming technological age.

As the machines become more sophisticated, they invite us to think boldly about how automation can reshape routine processes and push boundaries. The commitment to continuous improvement ensures these machines will remain relevant and powerful. But there's an intriguing final twist...

Collaborations between technologists, manufacturers, and users drive the evolution of these machines, where feedback loops foster enhancements and new uses. This partnership is a model for future innovation—a testament to how technology and humanity can advance hand-in-hand.

As you reflect on the possibilities, remember, automation doesn't mean replacing human creativity. Instead, it's an enabler, paving the way for ingenuity. We now reach the conclusion of this exploration, leaving a question burning: how will you harness this transformative technology in your own journey?

In the world of automatic wire stripping machines, one thing is clear: the potential far exceeds mere functionality. They're changing how we work and think, unlocking new dimensions of possibility and productivity. So, what now? Embrace the future, share these insights, and dive into a world where technology meets endless potential. Whether you’re a seasoned professional, a curious creator, or someone standing on the edge of innovation, now’s your time to leap forward and see where this journey takes you.