Imagine a world where manufacturing is faster, cheaper, and more precise than ever before. Laser cutting technology is not just a futuristic concept; it's reshaping industries at an unprecedented pace.

As the demand for customizable and efficient production skyrockets, laser cutting emerges as a pivotal player — one that every manufacturer needs to understand to stay competitive. But what lies beneath the surface of this cutting-edge technology?

Did you know that laser cutting can save companies thousands in production costs by reducing waste material? This efficiency is driving a silent revolution in product development. But that's not even the wildest part…

Beyond mere cost savings, laser technology enables unprecedented levels of design freedom—empowering creators to shape complex geometries that were once impossible. The implications are vast and widespread. But what happens next shocked even the experts…

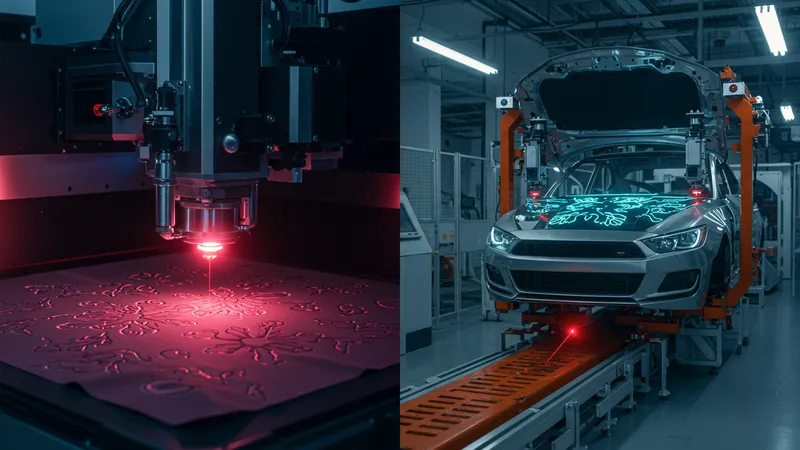

Laser cutting's precision is unmatched, achieving tolerance levels that traditional methods can't. This exactness is crucial for sectors like aerospace, where the margin for error is non-existent. But there’s one more twist… it drastically reduces the time needed for prototyping, transforming innovation cycles.

Industries are adopting laser technology not just for precision but for its versatility. Materials like metal alloys, plastics, and even glass can be efficiently cut. As a result, manufacturers cater to diverse market needs with ease. What you read next might change how you see manufacturing forever.

Many assume laser cutting is limited by material thickness. However, advanced machines can handle even thicker materials, contradicting common beliefs. This opens up avenues for large-scale architectural projects, previously thought impossible. But that’s not all.

Insiders know that laser cutting isn’t just about cutting. Engraving and marking features open new branding possibilities for companies seeking unique product differentiation. The next revelation could redefine how brands engage consumers.

Laser cutting reduces waste dramatically. With precision cutting, materials are utilized more effectively, resulting in significant cost savings for manufacturers. The benefits stretch beyond mathematics; they redefine production economics. But there’s a twist…

Despite high upfront costs, laser systems often pay for themselves quickly. The reduced labor and time costs mean that ROI can be achieved in record time, challenging traditional financial models. Some businesses have seen returns in just six months.

Interpretations of cost often miss hidden advantages. For instance, faster prototyping leads to quicker market entry, enhancing competitive edge. The speed at which you read about these benefits might just alter your business strategies.

With energy-efficient designs, modern laser machines are also reducing environmental impact. This aligns with global trends towards sustainable practices, making laser cutting an even more attractive choice for conscientious manufacturers.

Laser cutting provides design freedom unparalleled by other manufacturing technologies. Complex geometries are no longer bottlenecks, but pathways to innovation. Imagine creating structures without considering traditional limitations—this is the new reality.

For designers and engineers, this means no longer being constrained by what is physically feasible. Every imaginable creation is within reach, limited only by your creativity. And there’s more…

The ability to switch designs quickly and without retooling saves time and money, empowering rapid response to market changes. Agile manufacturing is becoming the taken-for-granted expectation, rather than the exception.

This new design flexibility allows customization at scale. Consumers now demand personalized products, and laser cutting allows manufacturers to meet these demands like never before. What happens next in consumer technology could surprise even the boldest futurists.

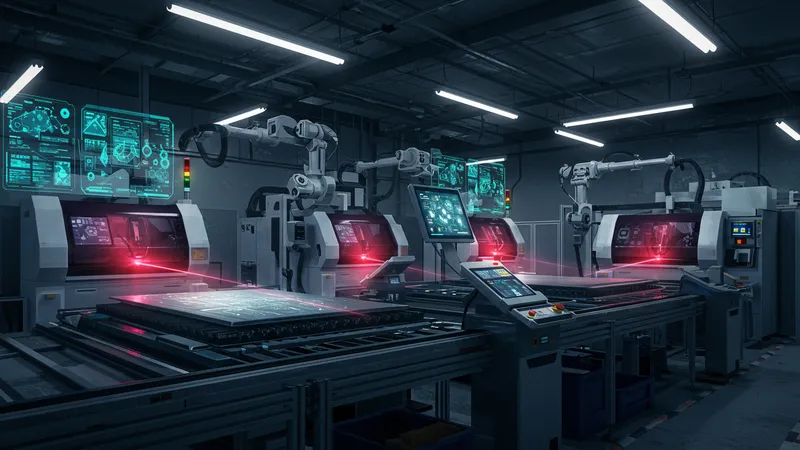

Laser technology is at the heart of smart manufacturing. With advancements in AI and machine learning, laser systems are becoming increasingly autonomous. This self-optimization means high precision with minimal human intervention.

The integration of smart technology allows machines to communicate, monitor, and troubleshoot in real-time. The effect is a streamlined production line that maximizes efficiency while minimizing downtime. But that’s just scratching the surface…

Predictive maintenance, facilitated by smart laser systems, anticipates equipment failure before it happens, reducing unexpected costs. This innovation not only saves money but also ensures uninterrupted production cycles.

As industries continue to embrace smart manufacturing, the synchrony between design and production becomes seamless. This convergence could lead to groundbreaking products that change our daily lives, bridging the gap between imagination and reality.

Industries once resistant to change are witnessing a transformation through laser technology. Even conventional sectors like textiles and automotive find unprecedented efficiency and creativity with this technology.

The textile industry uses lasers to create intricate patterns swiftly without fraying or damage, reviving the art of fabric design. Similarly, the automotive sector benefits from precise parts fitting, elevating safety and performance standards.

However, it's not just about innovation; it's about revitalization. Industries are shedding old inefficiencies and driving forward with renewed vigor. This evolution is not just expected; it’s demanded by a competitive market.

With these shifting dynamics, businesses must adapt or fall behind. Laser cutting serves as both a tool and a symbol of modernizing traditional practices, ensuring that industries don't just survive but thrive. This metamorphosis might completely alter how we define manufacturing success.

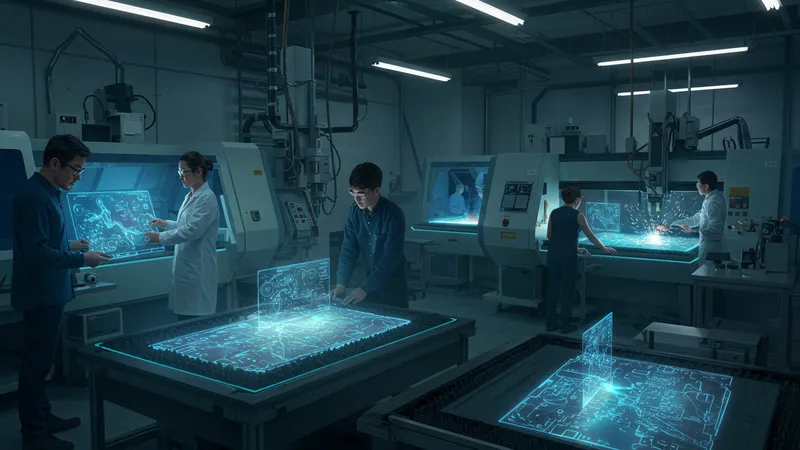

The adoption of laser technology necessitates a workforce proficient in its use. Educational institutions are now updating curricula to include laser engineering and design, preparing students for the future.

Training programs focus on both the technical prowess needed to operate sophisticated machines and the creative thinking required for innovative design applications. This dual approach ensures a holistic understanding of laser cutting’s potential.

Industries partnering with educational entities facilitate hands-on learning opportunities, bridging the gap between theory and practice. This collaboration not only benefits students but also ensures industries have access to a skilled workforce.

The rising demand for laser technology specialists hints at shifts in job markets and career paths. The next chapter in employment trends could hinge heavily on this technological paradigm shift, but there’s much more to explore.

As environmental concerns grow, companies look to laser technology for more sustainable manufacturing. Its precision reduces waste and energy consumption, aligning with greener manufacturing goals.

However, sustainability isn’t merely about waste reduction. Efficient resource use and longer product lifetimes also play significant roles. Lasers can extend the life cycle of materials by enhancing product durability through accurate production.

Many manufacturers have begun promoting their use of laser technology as part of their sustainability initiatives. This isn’t just good PR; it’s becoming a market requirement. But the implications go deeper…

The trend towards sustainable practices is urging global regulatory bodies to adjust guidelines, pushing even hesitant manufacturers toward greener solutions. Laser cutting’s compatibility with these evolving norms could redefine industry standardization.

Investment in laser technology represents a commitment to future-proofing manufacturing processes. While initial costs might seem high, the long-term economic benefits are undeniable.

The rapid cycle from design to production facilitated by lasers diminishes manufacturing lead times, ensures quicker market entry, and boosts profit margins. This agility renders businesses more adaptable to economic fluctuations.

Laser cutting systems’ reliability and longevity minimize repair and maintenance costs, delivering consistent financial predictability. The tangible shift in economics could influence how global trade and industry evolve.

Finance departments now consider technological investment as imperative, aligning budgets with growth outlooks. This interconnected decision-making framework heralds a new era in financial strategizing, and the ramifications may be broader than anticipated.

Personalization is transforming consumer expectations, and laser cutting is at the forefront of this revolution. Products can be uniquely customized to meet individual preferences without mass production constraints.

This capability allows for bespoke designs at a fraction of previous costs, promising wider accessibility to customized goods. But the consumer benefits run even deeper…

Through laser technology, manufacturers can offer limited-edition and one-off designs that foster brand loyalty and cater to niche markets. The competitive edge gained from this customization could reshape consumer-product relationships forever.

Consumers are no longer passive recipients of products; they become co-creators, engaged in the design process. The future relationship between brand and consumer might look radically different, with unprecedented levels of interaction and satisfaction.

Laser cutting is not bound by local limits; its global implications are profound. As countries adopt this technology, manufacturing on a macro scale becomes more efficient and competitive.

The transfer of laser technology across borders facilitates innovation diffusion and equalizes development opportunities. But globalization has its nuances too…

Balancing access to advanced manufacturing technologies with equitable innovation development could redefine international collaborations. Nations with this technology might lead in export advancements, influencing global market dynamics.

Reimagining global manufacturing standards will make international regulatory bodies more pivotal than ever, ensuring laser cutting technology is leveraged responsibly and sustainably worldwide.

Innovation thrives where there's room to experiment. Laser cutting provides unparalleled opportunities for R&D teams to push boundaries and upend technological limitations.

This environment nurtures disruptive inventions that could pivot industries in unexpected directions. But there’s one key insight…

The intersection of laser technology and innovative thought practices could inspire a new wave of industrial design standards, marrying art with engineering.

Such innovations remind us that technology isn’t static; it’s a vehicle for creative transformation, empowering industries not just to react to the present, but actively shape the future.

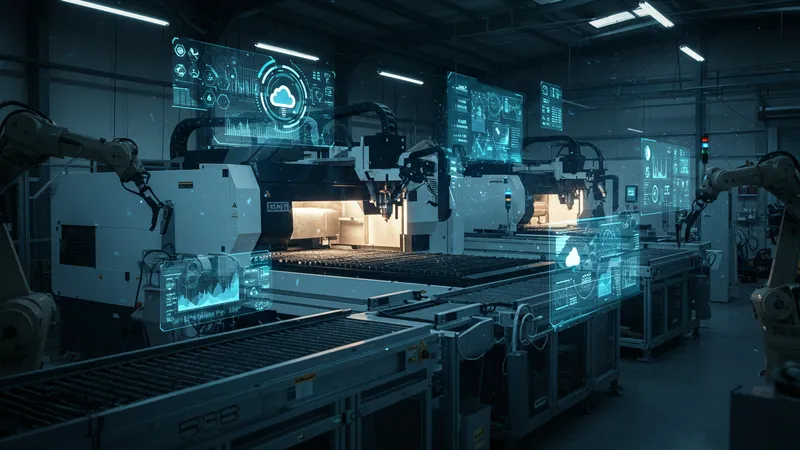

The integration of laser systems with other technologies, such as IoT and cloud computing, expands the potential of what’s possible. The data-driven insights gained allow companies to make more informed decisions.

This synergy ensures systems run optimally and adapt to real-time demands, creating fluid and responsive manufacturing lines. But what’s even more intriguing…

This advancement suggests a future where interconnected systems self-correct and enhance operational efficiencies autonomously, hinting at the dawn of smart factories.

As digital transformation accelerates, the strategic embedding of laser technology could hold secrets to unlocking unanticipated capabilities and business models yet to be imagined.

As technology reshapes work landscapes, laser cutting plays a role in redefining traditional employment paths and crafting new career opportunities.

This evolution prompts discussions about the balance between automation and human skills. It might challenge societal norms and what the workforce of the future looks like.

Industries and educational systems must collaborate to ensure a smooth transition for workers adapting to new technology roles. The societal fabric’s resilience hinges on proactive adaptation.

These developments could lead to a reevaluation of social models, potentially fostering innovative thinking around economic and social policies to support ever-evolving work ecosystems.

As we’ve seen, laser cutting is igniting a transformation in manufacturing that transcends industries. From cost efficiency to design innovation, its impact is far-reaching and profound.

The takeaway? Staying informed and adaptive is crucial, as those who embrace laser technology will lead in this dynamic landscape. Share this article, bookmark it, and take steps towards exploring how laser cutting could redefine your world. The revolution is here—are you ready to join it?