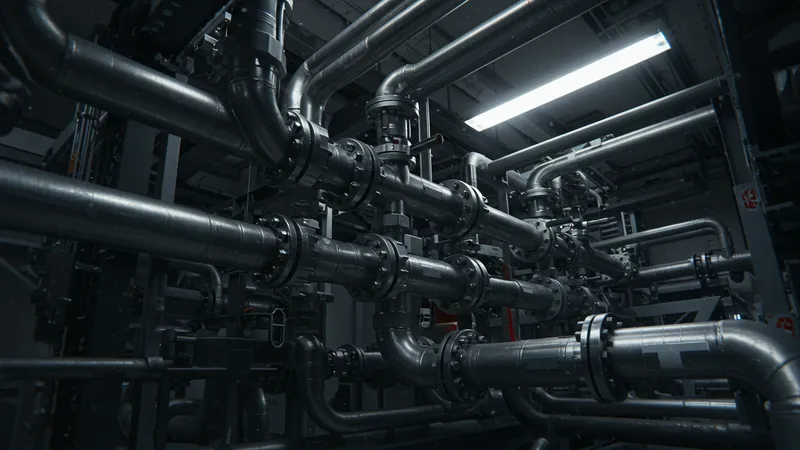

Imagine controlling the flow of water with the precision of a Swiss watch—hydraulic flow control solutions are revolutionizing industries in ways you’d never expect. But here's the kicker: what happens when things go wrong?

In a world increasingly reliant on fluid power systems, grasping the nuances of hydraulic flow control has never been more crucial. With risks lurking beneath the surface, understanding these systems could mean the difference between efficiency and disaster.

Traditional systems might seem straightforward, but hidden beneath these operations are complexities that could boggle the mind. For instance, did you know some hydraulic failures can result in losses reaching thousands of dollars? But that’s not even the wildest part…

Adopting the right flow control techniques isn't just about saving money—it’s about unlocking new levels of performance and reliability. Engineers are on the brink of breakthroughs that could shift paradigms worldwide. What’s driving this surge in innovation? It might just surprise you…

The real question: What happens next shocked even the experts…

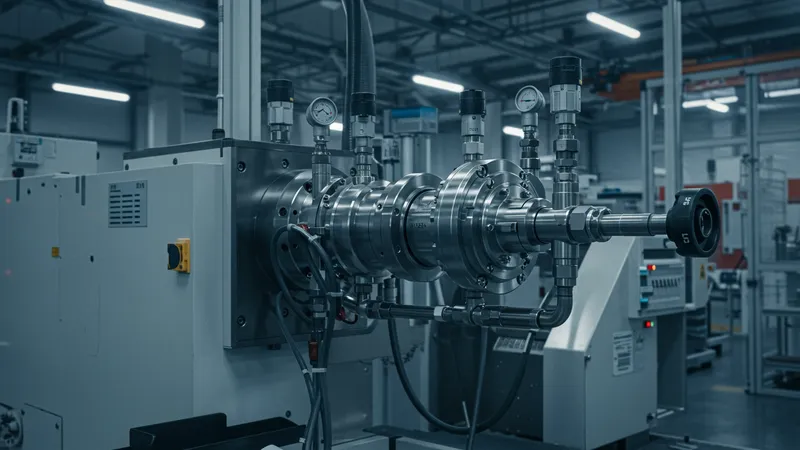

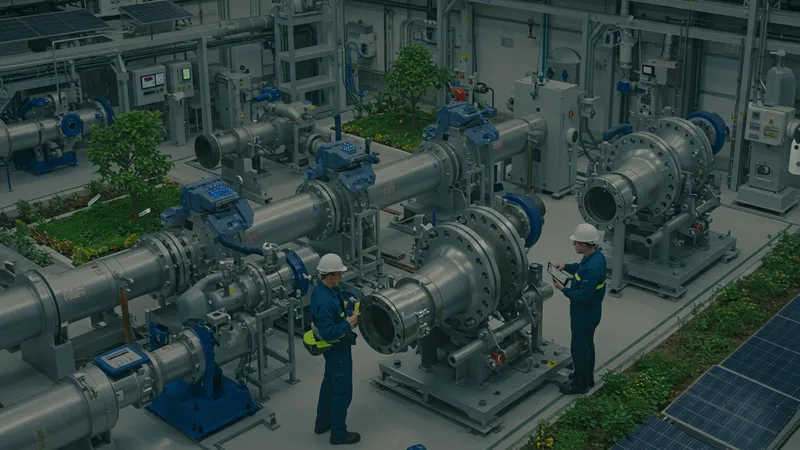

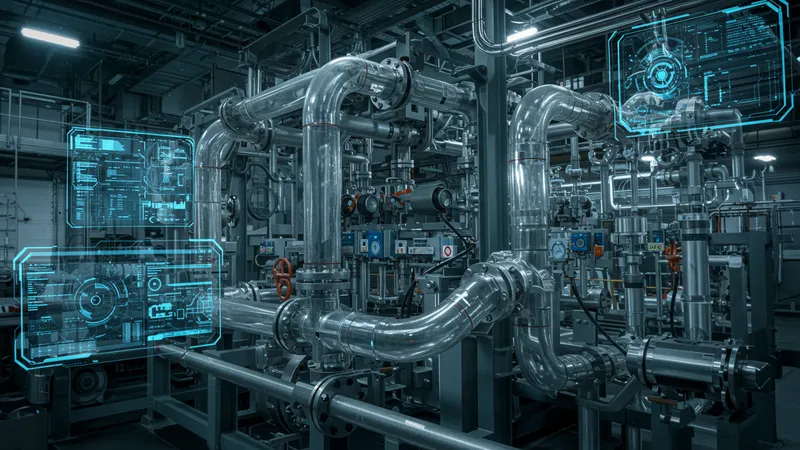

The intricate dance of hydraulic flow control is more than just pressure and fluid dynamics. It’s about precision engineering that can scale to any application, from the smallest vehicle components to the most massive industrial machines. The precision in tools ensures that every ounce of pressure is accounted for, cutting down errors significantly. But there’s one more twist…

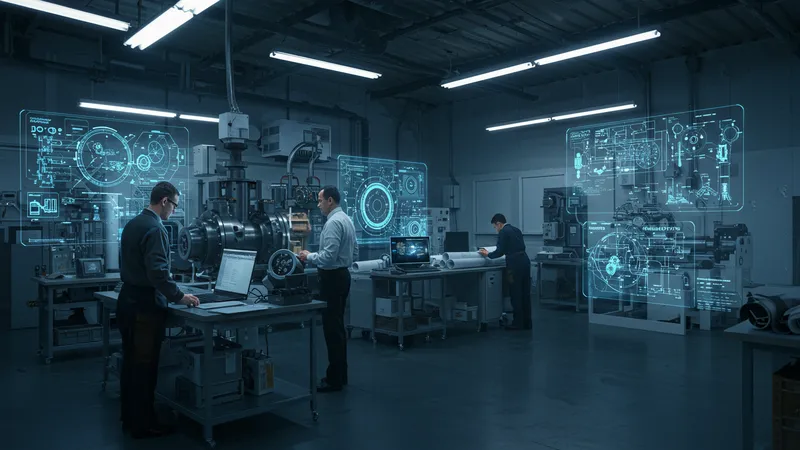

Unexpected advancements in sensor technology have allowed engineers to pinpoint inefficiencies with astonishing accuracy. By integrating intelligent sensors, companies are not only saving energy but also prolonging the lifespan of their machinery. This integration of smart technology might seem futuristic, but it’s already here, unfolding quietly across industries.

This capability to monitor and fine-tune hydraulic systems in real-time is revolutionizing how industries envision maintenance. Forget about unexpected downtimes; the age of predictive maintenance is upon us. And it just might save millions for companies every year. What you read next might change how you see this forever.

However, the real innovation lies in the symbiosis between human expertise and machine efficiency. This partnership is crafting new pathways to innovation that were once thought impossible. There’s still more to uncover about the critical role humans play in this high-tech landscape…

Smart flow control systems are creating waves across various sectors, redefining the way businesses operate. Integrating AI with hydraulic systems, companies are unlocking potential that transcends traditional limitations. AI isn't just a buzzword; it’s the brain behind these evolving systems.

With smart flow technology, facilities are seeing an upsurge in productivity like never before. Efficiency metrics are hitting new heights, thanks to real-time data analysis. Managers have more control and insight, allowing them to make informed decisions faster than ever. This transition, however, brings another shocker…

The challenge now is adapting to the rapid technological adoption. Many firms struggle to catch up, either due to budget constraints or resistance to change. Those who embrace this shift early are paving the way for future industry standards and reaping the rewards along the way.

As industries evolve, hydraulic experts must continuously adapt and innovate to stay ahead. Those who fail to innovate will be left behind, but for brave pioneers, the next discovery might just be around the corner, waiting to alter the landscape drastically.

The holy grail of modern industry lies in the elusive pursuit of maximum efficiency. While traditional systems have long been the backbone of various operations, the pursuit of innovation is leading to some surprising revelations.

Hydraulic systems are being redesigned from the ground up with efficiency at the forefront. This isn’t just about cutting costs; it’s also about sustainability and shrinking carbon footprints. Enhanced systems reduce waste, save energy, and ultimately reduce environmental impact.

One fascinating development has been the shift towards decentralized systems. These allow for flexible configurations that can be customized for specific needs, maximizing efficiency for each unique application. But that's just scratching the surface…

The future of hydraulic flow control doesn't just rest on technology; it’s also about the cultural shift within industries. By fostering an environment that prioritizes innovation, companies can unlock unprecedented levels of creativity and progress. But how far can this revolution truly go?

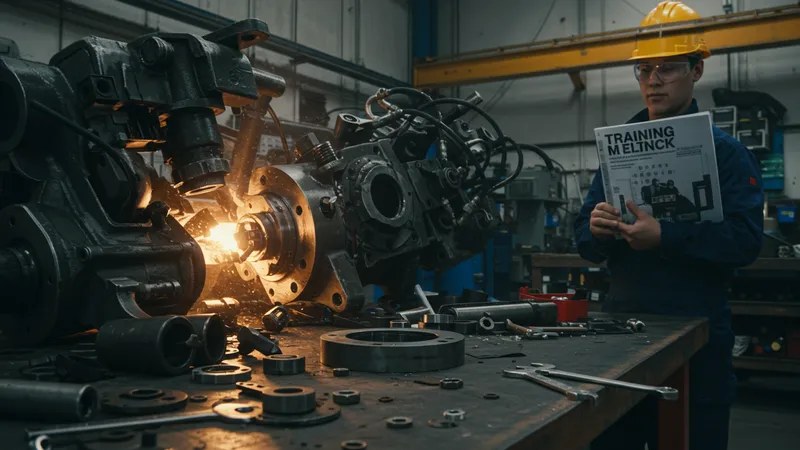

The financial repercussions of poorly managed hydraulic systems can reach staggering heights. Every breakdown is not just an inconvenience but a potential financial disaster. Hidden costs like unexpected repairs and operational downtime can cripple budgets swiftly.

Surprisingly, the key to mitigating these risks lies in education and training. Investing in employee expertise and proactive maintenance plans can prevent financial losses, ensuring systems run smoothly and efficiently.

Training programs and certifications offer tangible benefits, increasing the reliability of systems across the board. Yet many industries overlook this essential investment, choosing to save costs only to lose more in the long run.

The real surprise? The most successful firms are those that prioritize continuous learning and development. It’s this mindset that sets apart industry leaders from followers—propelling them towards newfound success and sustainability.

Despite the surge in automation, human intuition remains an irreplaceable asset. Engineers bring vital insights that machines simply cannot replicate, guiding the intricate design and implementation of hydraulic systems.

Interestingly, in a digital age, the human touch becomes even more crucial. Balancing machine efficiency with human experience leads to the creation of systems that are not only effective but resilient and adaptable.

The collaboration between humans and machines creates a synergy that pushes boundaries further than ever before. It encourages innovation and spurs on breakthroughs that redefine standards across industries.

But the reliance on human intuition carries its own challenges. As the industry evolves, adapting training and development programs is essential to cultivate the next generation of engineers who can navigate this complex terrain.

As technology advances, so too does the ambition of those who wield it. Hydraulic systems are no longer constrained to predictable environments. They are pushing into new territories—space exploration being one of the most exciting.

Yes, hydraulic systems are being tested for their potential use in off-world colonies, offering solutions for resource management and environmental control in inhospitable climates.

These explorations aren’t just theoretical; experimental projects are already underway, bringing hydraulic flow control into entirely new realms of application. This ambitious pursuit is redefining what’s possible as we extend our reach beyond Earth.

As these frontiers open up, they offer a myriad of possibilities that could redefine industries back on Earth, showcasing the boundless potential of hydraulic systems when they're combined with visionary thinking.

The push for greener practices has put hydraulic systems in the spotlight. As industries strive to reduce their carbon footprint, hydraulic flow control presents a unique opportunity to drive change.

By focusing on sustainability, hydraulic systems are being redesigned to utilize fewer resources without sacrificing efficiency. These changes can lead to a significant reduction in energy consumption and waste.

Interestingly, consumer demand is also steering industries toward more sustainable practices. In a world increasingly aware of environmental impact, businesses are finding that greener solutions are not just responsible but profitable.

One compelling aspect is the shift towards sourcing materials and technologies that aim to minimize harm to the planet. This reflects a growing trend that blends environmental responsibility with industrial efficiency.

Retrofitting existing systems with modern hydraulic flow control technologies offers a surprising array of benefits. It isn’t just about updating old machinery; it’s about transforming entire processes to improve efficiency and reliability.

Retrofitting can breathe new life into aging systems, increasing their lifespan while enhancing performance. These upgrades can reduce the need for new machinery, which saves costs and resources.

Moreover, retrofitting offers a unique opportunity to customize systems tailored specifically to the needs of a particular application, ensuring max efficiency and performance.

The unexpected twist? Retrofits often lead to creative solutions that were previously unthought of, pushing the boundaries of what is possible. These innovations often provide competitive advantages that redefine industry standards.

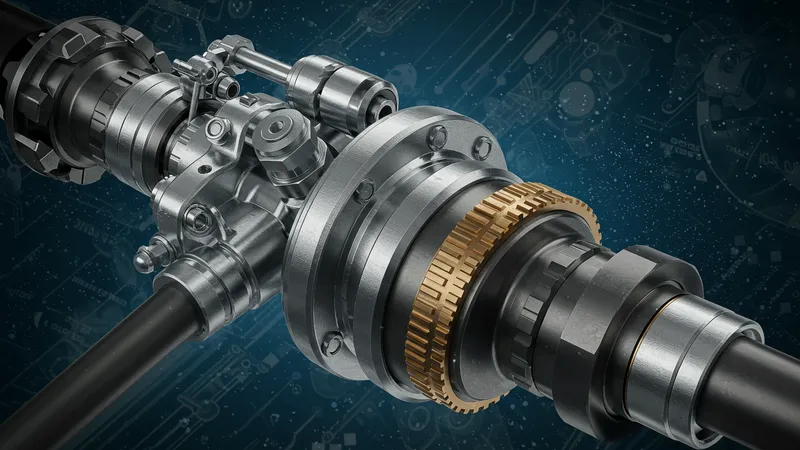

Material selection is vital in hydraulic systems, and recent advances have shed new light on its importance. Choosing the right materials can enhance system durability, performance, and efficiency in unexpected ways.

The impact of materials goes beyond systems; it influences ecological footprints, cost-efficiency, and operational lifespan. Recent developments in material science are driving major advancements, offering new possibilities.

These advancements are often surprising in their scope and potential. For example, lighter materials can lead to more efficient systems without sacrificing strength or reliability, opening new avenues of application.

Understanding the deeper implications of material selection is critical for companies aiming to stay ahead. It’s a perfect blend of science and strategy that promises long-term benefits for those willing to innovate.

Hydraulic flow control systems are making their mark far beyond traditional industrial settings. From entertainment to agriculture, these systems are finding unexpected applications that might surprise even industry insiders.

Take, for example, their use in theme parks for safety and performance. These systems ensure rides operate smoothly and safely, providing thrill-seekers with seamless experiences.

In agriculture, hydraulic systems help optimize irrigation processes, leading to more efficient water use and healthier crops. They’re quietly transforming the way we grow food.

The surprise? These systems are often behind-the-scenes heroes, delivering results without the fanfare and proving they're indispensable in a variety of sectors. It's a testament to the adaptability and versatility of hydraulic flow control.

Automation is reshaping the traditional approach to hydraulic systems. The integration of robotics and hydraulic flow control is paving the way for unprecedented operational efficiencies.

Surprisingly, automation doesn’t only streamline processes; it drastically reduces human error, leading to safer and more reliable systems. This shift toward robotic assistance is transforming industries.

As these technologies evolve, they provide opportunities to innovate further, creating hybrid systems that cater to advanced requirements while maintaining efficiency.

The real intrigue lies in the possibilities automation presents, which include transforming entire sectors with increased output, efficiency, and adaptability. It reveals a future rich in potential.

Innovation in hydraulic flow control is breaking barriers and challenging norms. Emerging technologies are redefining standards and reshaping industries globally.

Recent innovations have introduced unexpected capabilities that push systems beyond previous limits, showcasing the innovative spirit that drives progress.

This relentless pursuit of excellence uncovers endless possibilities, setting new benchmarks and expanding the realm of what’s achievable through technology.

The future is exciting, with bounds of potential waiting to be tapped. As industry leaders push forward, they continue to innovate, explore, and redefine what’s possible… unveiling a world rich in opportunity.

In the world of hydraulic flow control, innovation meets expertise to reshape industries and redefine possibilities. This journey into a rapidly evolving landscape showcases the potential of technology to transform the world as we know it. To embark on your own exploration of hydraulic excellence, share this knowledge and take the leap into the future by diving deeper into these surprising, innovative solutions.