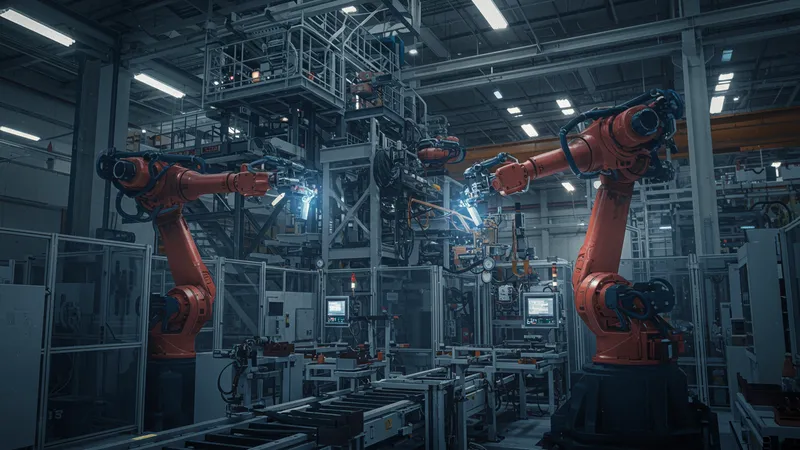

Industrial machines are the silent engines driving the modern world, seamlessly blending brute force with remarkable finesse. The concept at hand involves exposing how these sophisticated systems offer a rare combination of immense power and astonishing precision. From the assembly lines that fuel mass production to the robotics that conduct micro-level tasks, industrial machinery continuously redefines the benchmarks of efficiency and accuracy—making what once seemed impossible, now routine.

Diving beneath the surface, one finds layers of intelligence and engineering mastery underpinning today’s machinery. Sensors, AI-driven control systems, and custom-configured hardware enable industrial machines to deliver precision on sub-millimeter scales, even in demanding fields like aerospace and automotive. The journey to uncover the depth of these capabilities starts with examining concrete examples of where power meets precision.

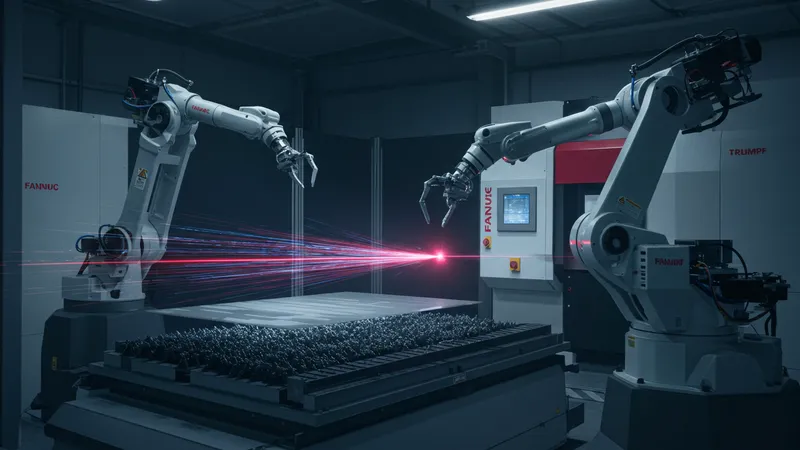

Leading industrial robots like FANUC play a pivotal role in streamlining mass production without sacrificing fine tolerances. Their adaptability enables tasks from delicate electronics manipulation to heavy automotive work, proving that power need not compromise accuracy. The robust build ensures reliability, while advanced programmability makes them indispensable in automated settings.

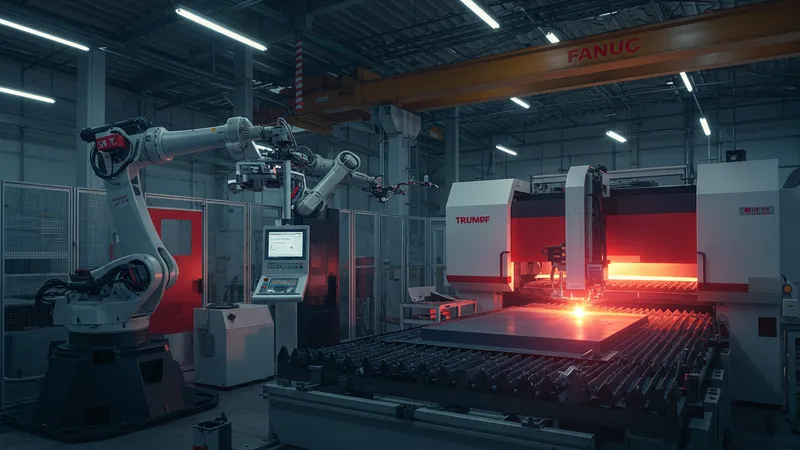

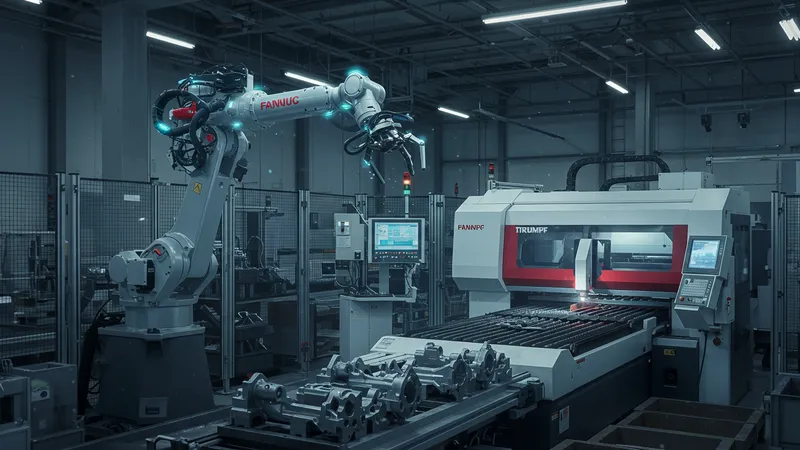

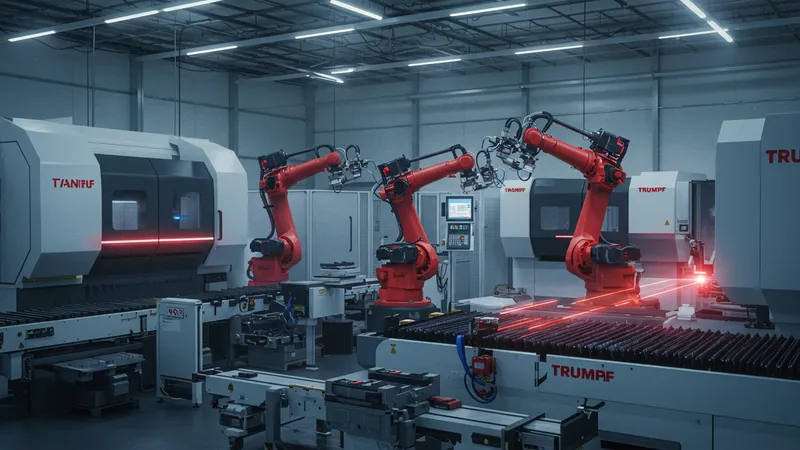

TRUMPF’s fiber laser cutting machines exemplify the pursuit of flawless precision in material processing. These tools cut metals with speed and accuracy measured in microns, reducing waste and enabling manufacturers to deliver complex designs with minimal error. The blend of high energy output and fine-tuned beam control demonstrates a true leap in industrial capability.

CNC machining centers by Mazak are revered for transforming metal blocks into intricate parts through programmable, repeatable actions. Their secret is marrying immense cutting force with tight tolerance control, benefiting aerospace and medical industries where errors are unacceptable. Flexible integration and user-friendly interfaces have brought CNC machining into virtually every sector where precision is non-negotiable.

Together, these examples reveal how industrial machines are far more than mere workhorses; they’re technological marvels pushing boundaries every day. As we continue to lift the veil on their true capabilities, the next layer of insight gets even more intriguing—prepare for a closer look at the forces, systems, and ingenuity behind this transformation. The deeper details reveal even more valuable insights ahead…

The range of power output among leading industrial machines shows the versatility of today’s machinery. FANUC robots are recognized for their ability to handle payloads ranging from just a few kilograms up to massive components. Their design allows for a rapid speed of operation, sometimes exceeding 2,000 millimeters per second. This strength, combined with precise articulation, supports both large-scale and highly detailed work without requiring tool changeovers or manual adjustment.

TRUMPF’s laser cutting equipment leverages advanced fiber laser sources capable of generating up to 12,000 watts of focused energy. This immense capability allows users to cut through thick sheets of steel quickly and consistently. Yet, the fine adjustment features—such as automated nozzle exchange and real-time feedback—ensure edges are smooth and measurements are exact, regardless of material hardness or complexity.

For Mazak’s CNC machining centers, performance is measured in both speed and repeatability. Spindle speeds can surpass 15,000 RPM, with automated tool changers enabling continuous operation. A critical factor is thermal stability—sensors monitor temperature to compensate for expansion or contraction, guaranteeing the final product’s dimensions remain exact throughout long production runs. Such performance is key for high-value sectors needing reliable, precision-focused outcomes.

Comparing these machines, it’s clear that engineers and decision-makers must carefully assess use case requirements. Not every task needs the raw power of a TRUMPF laser, nor the minute repeatability of a high-end CNC mill. Understanding the balance between force, speed, and precision ensures that businesses maximize both productivity and quality, whether for one-off prototypes or mass-produced components.

The marriage of digital technologies and mechanical engineering has radically transformed industrial machines’ capabilities. FANUC robots integrate artificial intelligence and vision recognition, allowing them to identify parts, adjust routines, and correct deviations without halting operations. This advancement reduces downtime, improves consistency, and minimizes errors—critical traits for manufacturers pursuing lean production processes or handling mixed product lines.

Laser cutting systems like those from TRUMPF benefit from real-time process monitoring. Sensors embedded in the cutting head measure factors such as temperature, beam focus, and surface reflections. This data is processed instantaneously to adjust energy output and motion, keeping tolerances within prescribed limits—even when dealing with varying material thicknesses or reflective surfaces. The result is fewer defects and greater material efficiency.

Mazak CNC machining centers have embraced complex software platforms and IoT connectivity. Operators can simulate machining cycles, analyze tool wear, and schedule preventive maintenance remotely. These “smart factories” optimize each phase of production, not only boosting throughput but ensuring that the most stringent standards of accuracy and surface finish are repeatedly met, even on challenging geometry or exotic materials.

These ongoing innovations don’t just increase output; they set new norms across manufacturing industries worldwide. With each generation, industrial machines become more autonomous, adaptable, and able to deliver scalable advantages—demonstrating that power and precision are no longer competing priorities but partners driving progress forward.

The adoption of powerful, precise machinery has led to significant benefits for manufacturers and their customers. FANUC robots speed up production lines, leading to shorter lead times and greater flexibility when switching between products. This efficiency results in consistent product quality and enables companies to respond quickly to changing market demands, solidifying their competitive position.

TRUMPF laser cutters are now integral in industries where flawless material processing is essential. Their exceptional edge quality reduces the need for secondary finishing and enhances the fit and function of parts in complex assemblies. For sectors like automotive and aerospace, this reliability ensures regulatory compliance and minimizes rework, lowering overall production costs without compromising quality.

Mazak CNC machining centers provide the foundation for producing high-precision components across medical device, energy, and electronics industries. Their ability to fabricate parts with minimal dimensional variance supports innovations in miniaturization and advanced engineering designs. This consistency helps maintain industry certifications and promotes trust among demanding clients who value predictability and repeatability in supplied components.

Wider adoption of advanced machines also raises the baseline for global industry standards. As organizations invest in higher-performing equipment, benchmarks shift upward, prompting regular reviews of tolerances, surface finishes, and testing protocols. This cycle propels innovation and prompts peer sectors to advance, ensuring sustained progress across the entire manufacturing landscape.

The horizon for power and precision in industrial machines is expanding rapidly. Robotics manufacturers such as FANUC are integrating greater levels of machine learning, enabling robots to adapt to completely new tasks with minimal programming. This flexibility opens the door for smaller production runs and customized products, all while maintaining exacting standards of performance and repeatability.

Laser technology is poised for even sharper improvements. TRUMPF and similar firms are exploring methods for dynamic beam shaping, where the characteristics of the laser can be tailored in real time to suit each project’s needs. This not only enhances cutting accuracy but also broadens the range of processable materials, including increasingly complex composites and metals.

In CNC machining, trends point toward autonomous work cells and 24/7 lights-out manufacturing. Mazak’s latest centers incorporate integrated measurement systems and remote diagnostics capable of detecting tool wear or deviations instantly. This ensures a virtually uninterrupted workflow, empowering manufacturers to meet heightened demands for speed, cost control, and ultra-tight tolerances.

As we look ahead, the evolution of industrial machines will continue to transform what is possible in manufacturing. The power and precision on display are not static achievements, but springboards for innovation—setting the stage for smarter factories, more efficient resources, and breakthrough capabilities that will reshape industries for years to come.